Technology

Technology of metal plating

The technology of making a surface of metal generating a hard coat is continuing evolution every day.

The technology of making a surface of metal generating a hard coat is continuing evolution every day.

There is hard chromium metal plating as one of the procedures which deposits the hardest coat with metal plating.

Hard chromium metal plating has the following features, and the use is various.

◆Since it is comparatively processible at low temperature (about 50℃), distortion by processing does not occur for a product.

◆If it is metal with turning-on-electricity nature, in almost all cases, it can plate.

◆Since adhesion is good and easy also for padding processing, many are used for the purpose of repair of a machine part.

◆Regeneration of metal plating is easy.

Two kinds of chromium plating baths adopted in our company occur.

One is metal plating by the Sargent bath, and higher hardness metal plating according [another] to a non-fluoridation bath.

Next, each trait is described.

| Sargent bath | Comparative Item | Nonfluorination bath(HEEF25) |

| 45℃~55℃ | Bath Temperature | 45℃~55℃ |

| 750~950HV | Plating Hardness/100gf | 950~1100HV |

| Good | Polish | Very Good |

| Good | Wear Resistance | Very Good |

| Good | Corrosion Resistance | Extremely Good |

| Good | Padding | Good |

| Good | Mold Parting | Extremely Good |

| Normal | Plating Speed | Fast |

| Good | Throwing power of Electrolytic Coloring | Extremely Good |

| Normal | The Number of micro cracks | Much |

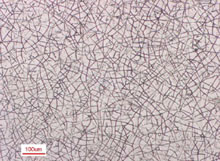

| Sargent (×100) The number of cracks: 765cracks/cm  |

Surface Crack's Pictures | HEEF25 (×100) The number of cracks: 1,710cracks/cm  |

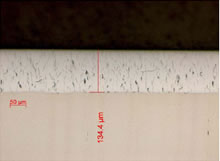

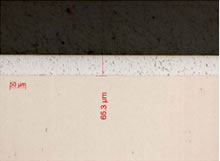

| Sargent (×200) film thickness: 134.4μm  |

Cross section’s Pictures | HEEF (×200) film thickness: 65.3μm  |

Various uses

◆Although it would be corrosion-resistant using SUS304 and he would like to make parts with the hard surface, since it cannot harden at parts, harden the surface with chromium metal plating.

◆Although he would like to make a light roller using aluminum, since aluminum is immediately worn out, it hardens a roller surface with chromium metal plating.

◆The nitriding treatment of the axis which performs nitriging treatment carries out chromium metal plating for the purpose of nitriding prevention to an unnecessary part.

◆When a product serves as short measurement by mistaken processing and there is no time to remake, rectify short measurement by padding processing by chromium (obtaining customer's comprehension) metal plating.

◆When intercalating parts in a shaft, in order to prevent galling from occurring, carry out chromium metal plating which has a grease slot (process a slot only into a metal-plating layer) in the part.

◆Repair the part worn-out by receiving the large load of the parts supporting a shaft by performing super-thick metal plating (not less than 300 micrometers).

◆Since a risk of metal plating exfoliating according to big load (big face pressure) is large, break off your relationship in a metal-plating layer as a measure which prevents a chain of ablation.